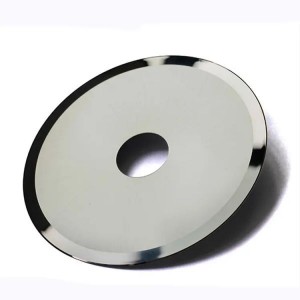

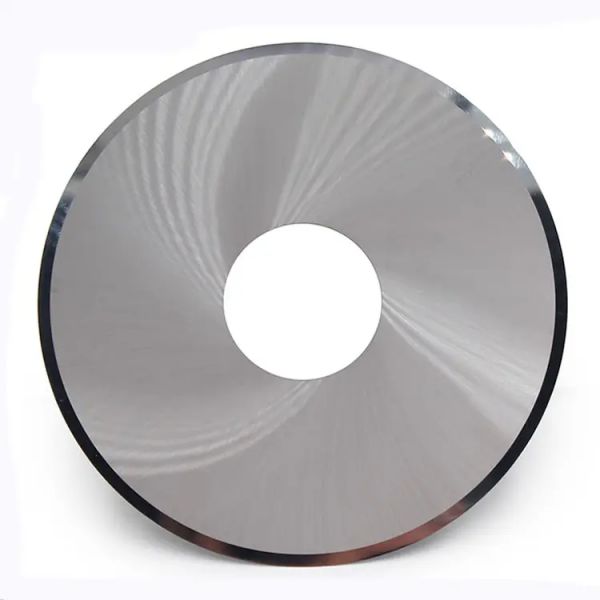

Fengke Tobacco Circular Slitting Knives

Features:

1. Improve durability and service life, 600% higher than standard steel;

2. Since the number of blade replacements is reduced, production efficiency is higher and downtime is shorter;

3. Due to reduced friction, cleaning and cutting are more precise;

4. Reduce the possibility of production line downtime to ensure stable production of equipment;

5. Better overall cutting performance in high-temperature and high-speed cutting environments

Product Size

| Number | Model No. |

| 1 | Φ100*Φ15*0.3 |

| 2 | Φ100*Φ16*0.3 |

| 3 | Φ70*Φ40*1 |

| 4 | Φ70*Φ50*1 |

| 5 | Φ80*Φ50*1 |

| 6 | Φ80*Φ55*1 |

| 7 | Φ120*Φ55*1 |

| 8 | Φ100*Φ60*1 |

| 9 | Φ120*Φ60*1 |

| 10 | Φ60*Φ19*0.27 |

| 11 | Φ63*Φ19.05*0.3 |

| 12 | Φ64*Φ19.05*0.3 |

| 13 | Φ85*Φ16*0.25 |

| 14 | Φ89*Φ15*0.3 |

| 15 | Φ92*Φ15*0.2 |

| 16 | Φ100*Φ15*0.2 |

| 17 | Φ100*Φ15*0.3 |

| 18 | Φ100*Φ15*0.35 |

| 19 | Φ100*Φ16*0.2 |

| 20 | Φ100*Φ16*0.3 |

| 21 | Φ100*Φ19*0.3 |

| 22 | Φ100*Φ45*0.2 |

| 23 | Φ100*Φ19*0.3 |

| 24 | Φ101.6*Φ25.4*0.28 |

| 25 | Φ110*Φ22*0.5 |

| 26 | Φ120*Φ56*1 |

Application:

These circular knives are applied to the requirements of Tobacco machines , like MK8, MK9, MK95, Protos 70/80/90, GD121, etc. We can provide different carbide grade materials for customers to choose.Also offer custom made service as per customers designs,drawings ,provide service of laser printing customer’s brand,logo or so on the knives.