Carbide Indexable knives are cutting tools that are made up of carbide. It is a combination of carbon and iron. The main property of this cutting tool is that it is very hard as well as wear-resistant. This type of cutting tool is used in various industries such as woodworking, metalworking, and machining. There are various types of carbide indexable knives available in the market such as turning knives, milling knives, and drilling knives. Each type of knife has its own specific function and application. In this blog post, we will discuss the different types of carbide indexable knives in detail and their uses in various industries.

What are Carbide Indexable Knives?

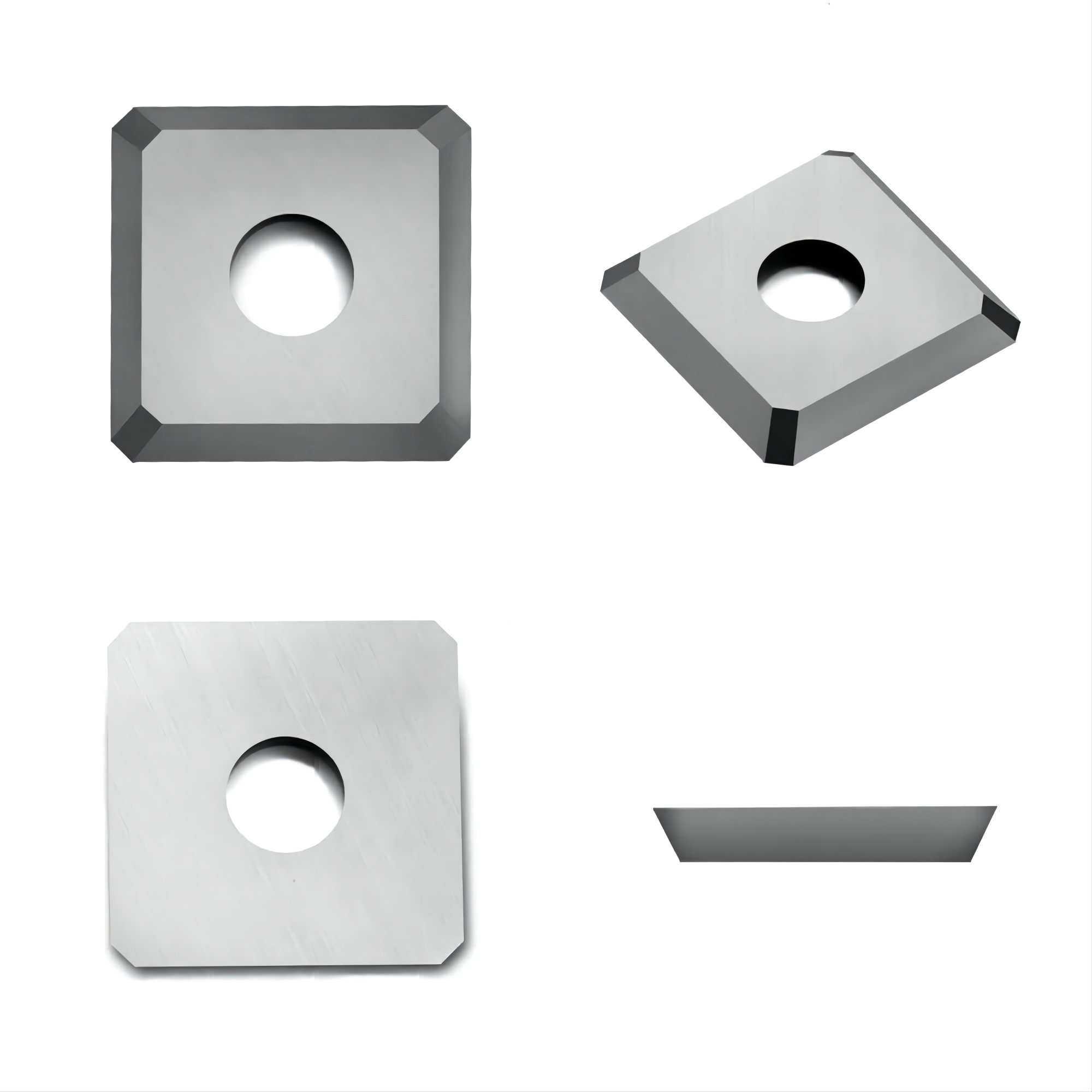

Carbide indexable knives are made from a solid piece of carbide that is machined into a knife shape. The blade is then coated with a wear-resistant material such as titanium nitride (TiN) or diamond-like carbon (DLC). These coatings help to protect the cutting edge of the knife and improve its durability.

The main advantage of using carbide indexable knives is that they can be resharpened many times without losing their original sharpness. This makes them ideal for repetitive cuts where a sharp blade is essential, such as in the food industry. Carbide knives also have a longer lifespan than traditional steel knives, meaning they will eventually pay for themselves in terms of cost savings.

If you are looking for an extremely durable and long-lasting knife, then a carbide indexable knife is the ideal choice. However, these knives do come at a higher price point than other types of knives on the market.

How do they work?

Carbide indexable knives are made from a hard, wear-resistant material called carbide. This makes them ideal for cutting through tough materials like metals and plastics.

Indexable knives have a cutting edge that is composed of small teeth, or "carbides." These teeth are arranged in a row and held together by a strong bond. As the knife is used, the carbides on the cutting edge wear down. When they become too worn to continue cutting effectively, they can be replaced with new ones.

This type of knife is very versatile and can be used for a variety of applications. Indexable knives are often used in woodworking, metalworking, and plastic fabrication.

Advantages of Carbide Indexable Knives

There are many advantages of carbide indexable knives over other types of knives. Carbide indexable knives are more durable and last longer than other types of knives. They are also easier to sharpen and don’t require as much maintenance.

Carbide indexable knives are made from a harder material than other types of knives, so they stay sharper for longer. This means that you won’t have to sharpen them as often, which can save you time and money. They are also less likely to chip or break, so you can use them for tougher cutting jobs.

Another advantage of carbide indexable knives is that they require less maintenance. Because they are made from a harder material, they don’t need to be oiled as often. This means that you can save time and money on knife maintenance.

If you are looking for a durable and long-lasting knife, then a carbide indexable knife is a good option. They are also easy to sharpen and require less maintenance, so you can save time and money in the long run.

The Different Types of Carbide Indexable Knives

There are many different types of carbide indexable knives available on the market today. Each type has its own unique set of characteristics and benefits that make it ideal for specific applications. Here is a brief overview of the most popular types of carbide indexable knives:

1. High-Speed Steel (HSS) Carbide Indexable Knives: HSS carbide knives are made from a high carbon steel that is coated with a thin layer of carbide. This type of knife is designed for use in high-speed machining applications where extremely sharp edges are required. HSS carbide knives can maintain their edge up to five times longer than conventional high-speed steel blades and can resist heat build-up better than uncoated blades.

2. Titanium Carbide Indexable Knives: Titanium carbide knives are made from a titanium alloy that is coated with a thin layer of carbide. This type of knife is designed for use in high-temperature applications where excellent wear resistance is required. Titanium carbide knives can maintain their edge up to ten times longer than conventional titanium blades and can resist heat build-up better than uncoated blades.

3. Cemented Carbide Indexable Knives: Cemented carbide knives are made from a tungsten carbide alloy that is bonded together with cobalt or other metal alloys. This type of knife is designed for use in heavy-duty machining applications where superior wear resistance and toughness are

Conclusion

Carbide indexable knives are a versatile and convenient option for anyone looking for an easy way to cut through materials. With the right knife, you can easily tackle a variety of projects, both big and small. We hope that this article has given you some basic knowledge about carbide indexable knives so that you can make an informed decision about whether or not they're the right choice for you.

Post time: Oct-11-2022