Carbide inserts for wood are small, cutting tools made of tungsten carbide, a super-hard material. They are used in woodworking machinery such as routers and shapers to cut, shape, and finish wood products. They offer high precision and long lifespan compared to traditional steel cutting tools. They can be used for a variety of woodworking tasks such as grooving, mortising, and shaping.

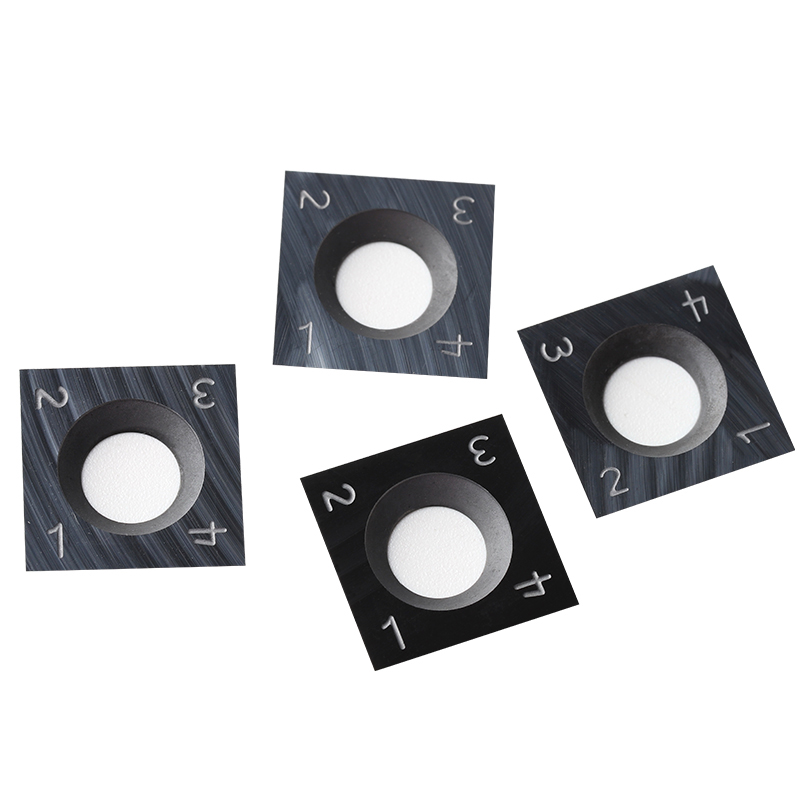

Carbide inserts for woodworking are small cutting tools that are used in place of traditional cutting tools, such as saw blades and router bits. They are made from carbide, a very hard and durable material, and are typically square or rectangular in shape with sharp cutting edges. They are commonly used in CNC machines and are ideal for cutting and shaping hardwoods, softwoods, and engineered woods, as well as for creating decorative edges and joints. Some advantages of using carbide inserts for woodworking include their longevity, accuracy, and ability to make precise cuts quickly and efficiently.

They are available in a variety of shapes and sizes to suit different cutting needs, such as straight cuts, curves, and decorative edges.

Square Insert: Used for general purpose turning and facing operations.

Diamond Insert: Ideal for cutting non-ferrous metals and abrasive materials.

Round Insert: Used for profiling and contouring operations.

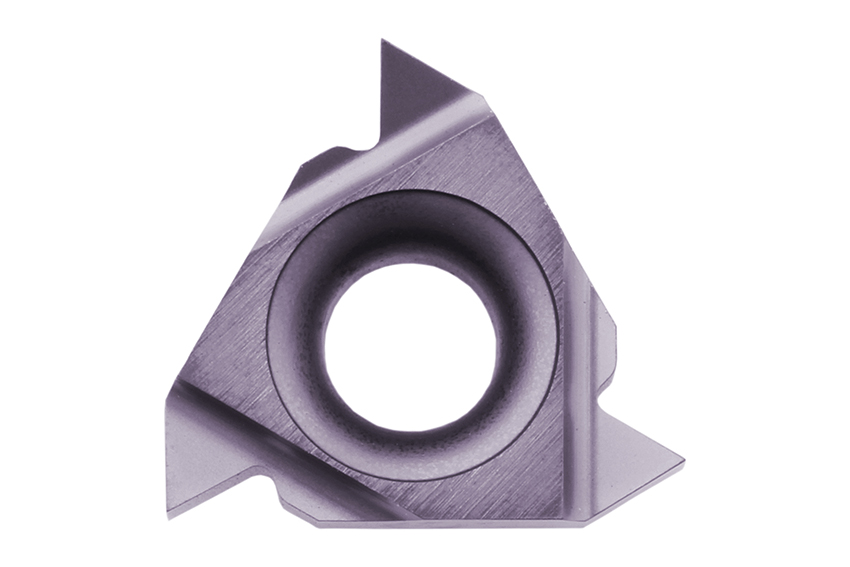

Triangle Insert: Used for grooving, parting, and threading operations.

Negative Rake Insert: Used for heavy duty cutting operations, such as roughing and interrupted cuts.

Positive Rake Insert: Used for finishing operations, such as fine surface cuts.

T-slot Insert: Used for T-slot milling operations.

Threading Insert: Used for internal and external threading operations.

Parting Insert: Used for separating workpieces by cutting a groove.

Profiling Insert: Used for complex shaping and contouring operations.

Post time: Jan-31-2023