When it comes to woodworking, planer blades play a crucial role in achieving smooth and precise cuts. Two popular types of planer blades on the market are TCT (Tungsten Carbide-Tipped) and HSS (High-Speed Steel). In this blog post, we'll explore the key differences between TCT planer blades and HSS planer blades, helping you make an informed decision on which option is best suited for your woodworking needs.

-

Understanding TCT Planer Blades

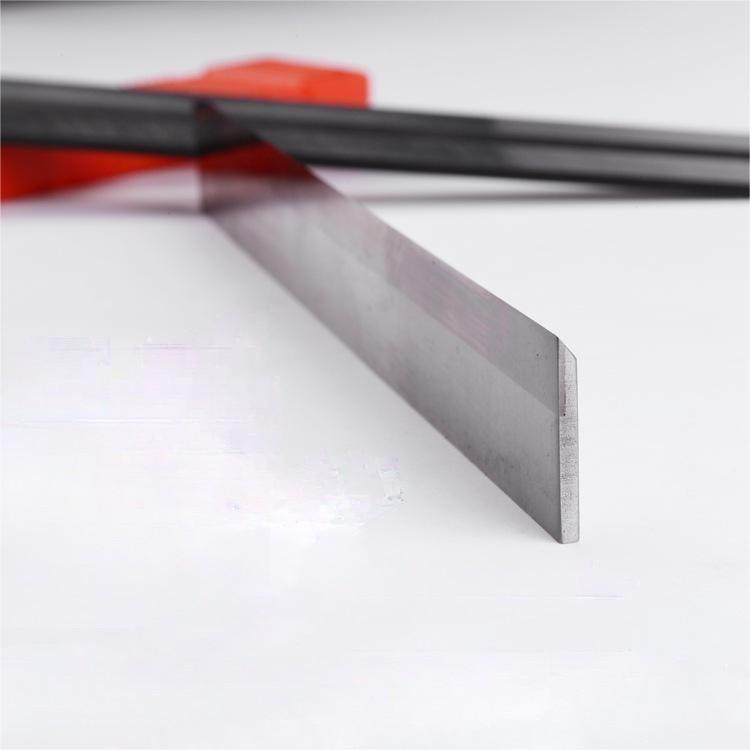

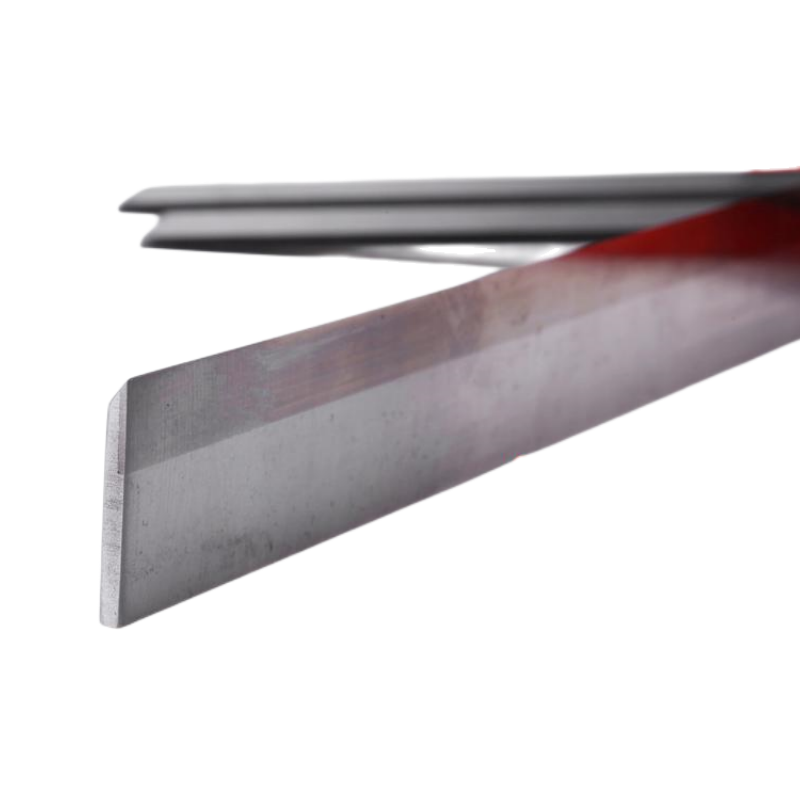

TCT planer blades are renowned for their durability and longevity. They feature a high-quality steel body with small tungsten carbide tips brazed onto the cutting edge. Tungsten carbide is an extremely hard and wear-resistant material, making it perfect for demanding woodworking applications.

Advantages of TCT Planer Blades:

a. Exceptional Durability: TCT planer blades are designed to withstand heavy use and can endure prolonged cutting without losing their sharpness. This durability translates to reduced blade replacements, saving you time and money in the long run.

b. Versatility: TCT planer blades are suitable for various types of wood, including hardwoods and softwoods. They excel at cutting through tough materials, providing clean and precise results.

c. Enhanced Cutting Performance: The sharpness and hardness of tungsten carbide tips allow TCT planer blades to make smooth cuts with minimal tear-out. They can handle challenging grain patterns and difficult woodworking tasks effectively.

-

Exploring HSS Planer Blades

HSS planer blades are made from a special type of high-speed steel that retains its cutting edge even at elevated temperatures. HSS blades are known for their excellent sharpness and ease of sharpening, making them a popular choice among woodworkers.

Advantages of HSS Planer Blades:

a. Superior Sharpness: HSS planer blades are renowned for their sharpness and precision. They can provide exceptionally smooth finishes on a wide range of wood types, including hardwoods, softwoods, and even composite materials.

b. Ease of Sharpening: HSS blades are relatively easy to sharpen, making them a convenient choice for woodworkers who prefer maintaining their blades in-house. With proper care and maintenance, HSS planer blades can offer extended service life.

c. Cost-Effectiveness: Compared to TCT planer blades, HSS blades are often more affordable. If you have a limited budget or engage in woodworking as a hobbyist, HSS blades can provide a cost-effective solution without compromising on quality.

- Choosing the Right Option for Your Woodworking Projects

Selecting between TCT planer blades and HSS planer blades largely depends on the nature of your woodworking projects, your budget, and personal preferences.

- If you frequently work with tough, dense woods or encounter challenging grain patterns, TCT planer blades are an excellent choice due to their exceptional durability and cutting performance.

- On the other hand, if you work with a variety of wood types and prefer the ability to sharpen your blades easily, HSS planer blades offer superior sharpness and convenient maintenance.

Conclusion

Both TCT planer blades and HSS planer blades have their own set of advantages, and choosing the right option requires careful consideration of your woodworking needs. Whether you prioritize durability and long-term use (TCT blades) or sharpness and ease of sharpening (HSS blades), both options can deliver excellent results when used correctly.

Remember, investing in high-quality planer blades is crucial for achieving precise and smooth cuts, ultimately enhancing the quality of your woodworking projects. Take your time to assess your requirements and choose the planer blades that best align with

your needs, ensuring a successful and satisfying woodworking experience.

Technical information

|

item

|

TCT straight planer knife for wood planing

|

|

Applicable Industries

|

Wood planing

|

|

Material

|

TCT

|

|

Hardness

|

HRC 63

|

|

Advantage

|

Durable

|

|

Package

|

3 pcs per plastic pack

|

|

Surface condition

|

Vertical grinding,Horizontal grinding

|

|

Usage

|

planing machine,moulder machine,milling machine

|

Features:

1.100% virgin tungsten carbide make insert knife long lasted and more durable.

2. Providing superior smooth quality cuts every time.

3.Quick and precise replacements of dull knives.

4.Due to insert accuracy tool life is extended.

5.Special carbide grades for special applications.

6.Knives can be re-sharpened multiple times without affecting the original profile.

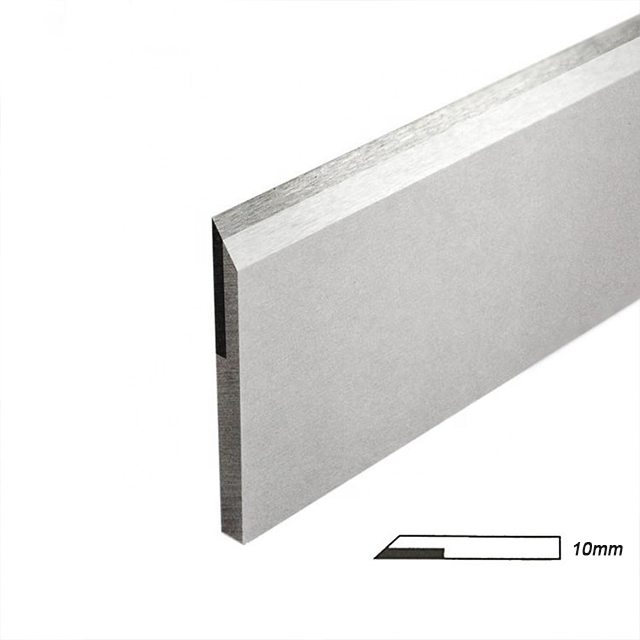

Specifications Of Standard Sizes:

|

产品编码

|

规格Size(mm)

|

Tip size(mm)

|

|

FKPBT10001

|

80*25*3

|

10mm

|

|

FKPBT10002

|

90*25*3

|

10mm

|

|

FKPBT10003

|

100*25*3

|

10mm

|

|

FKPBT10004

|

120*25*3

|

10mm

|

|

FKPBT10005

|

150*25*3

|

10mm

|

|

FKPBT10006

|

160*25*3

|

10mm

|

|

FKPBT10007

|

200*25*3

|

10mm

|

|

FKPBT10008

|

210*25*3

|

10mm

|

|

FKPBT10009

|

230*25*3

|

10mm

|

|

FKPBT10010

|

260*25*3

|

10mm

|

|

FKPBT10011

|

300*25*3

|

10mm

|

|

FKPBT10012

|

310*25*3

|

10mm

|

|

FKPBT10013

|

400*25*3

|

10mm

|

|

FKPBT10014

|

410*25*3

|

10mm

|

|

FKPBT10015

|

500*25*3

|

10mm

|

|

FKPBT10016

|

80*30*3

|

10mm

|

|

FKPBT10017

|

90*30*3

|

10mm

|

|

FKPBT10018

|

100*30*3

|

10mm

|

|

FKPBT10019

|

120*30*3

|

10mm

|

|

FKPBT10020

|

150*30*3

|

10mm

|

|

FKPBT10021

|

160*30*3

|

10mm

|

|

FKPBT10022

|

200*30*3

|

10mm

|

|

FKPBT10023

|

210*30*3

|

10mm

|

|

FKPBT10024

|

250*30*3

|

10mm

|

|

FKPBT10025

|

260*30*3

|

10mm

|

|

FKPBT10026

|

300*30*3

|

10mm

|

|

FKPBT10027

|

310*30*3

|

10mm

|

|

FKPBT10028

|

330*30*3

|

10mm

|

|

FKPBT10029

|

350*30*3

|

10mm

|

|

FKPBT10030

|

400*30*3

|

10mm

|

|

FKPBT10031

|

410*30*3

|

10mm

|

|

FKPBT10032

|

430*30*3

|

10mm

|

|

FKPBT10033

|

450*30*3

|

10mm

|

|

FKPBT10034

|

500*30*3

|

10mm

|

|

FKPBT10035

|

510*30*3

|

10mm

|

|

FKPBT10036

|

600*30*3

|

10mm

|

|

FKPBT10037

|

610*30*3

|

10mm

|

|

FKPBT10038

|

630*30*3

|

10mm

|

|

FKPBT10039

|

640*30*3

|

10mm

|

Packing&Delivery:

|

3pcs/box |

Delivery by UPS/DHL/FEDEX/EMS | |

| Shipping ways | Air transportation,Sea transportation,Land transportation,Express ,etc. | |

| Shipping Details | We can choose the fastest and economical shipping way for you. | |

Why choose us?

1.We specialize in the manufacturing of tungsten carbide cutting tools over 20 years.

2. We can offer you the highest precision knives due to our latest imported grinding machines.

3.Exclusive carbide grade for highest quality of cut,more durable.

4. Factory direct price can help you win more market.

Post time: May-16-2023