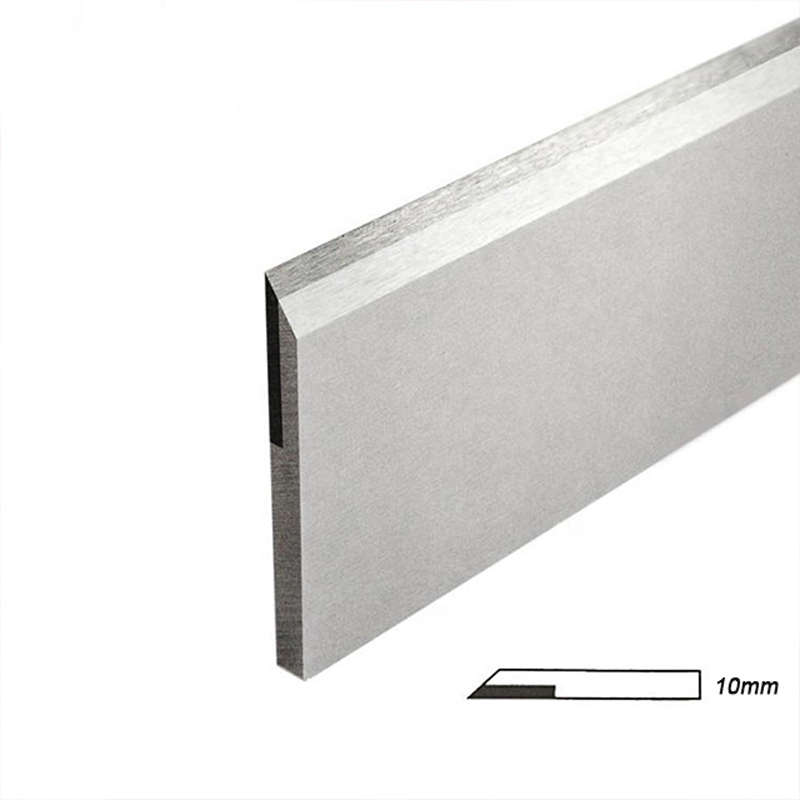

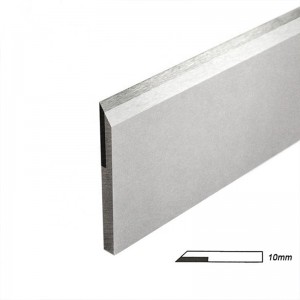

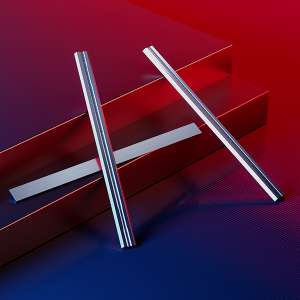

Tungsten Carbide Tipped Woodworking Planer Knife

What is application?

The main using purpose of Tungsten Carbide Strips is to make cutting tools for woodworking, like forming tools and different kinds of blades to cut Nature wood, HDF, MDF, Ply wood, Particle board and some non-metal material to make it straight Thin, thin and smooth for preset usage.

It is very important to select the right grade to match the using purpose, we have to consider the physical properties of the processing object, also the working condition for tools, like running speed, impact.

Why chooseFENGKE TOOL TCT finger joint cutter?

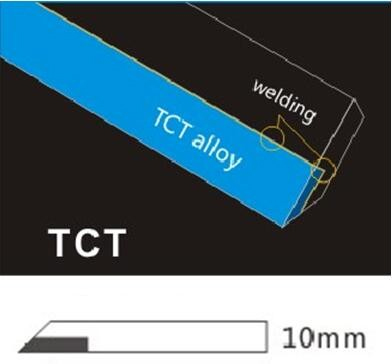

1. With features of good red hardness body, sharp and hard blade HRC90~91.

2. Edge straigtness erros<0.05mm, smooth planing surface.

3. Every set of planer knives are counterweight, this can strictly control the tolerance within 2 grams;

4. strong resitance to abrasion, industry-leading welding technology ensures solid inlay, no distortion and no crack.

5. Blade sharpening time can be decreased to least.

Specifications:

|

TCT10 regular size (10mm inlay) |

TCT10 irregular size (10mm inlay) |

||

| Item # | size (l*w*h) | Item # | size (l*w*h) |

| FKP01C10001 | 80*25*3*1.0 | FKP01S10001 | 300*30*4*1.0 |

| FKP01C10002 | 90*25*3*1.0 | FKP01S10002 | 400*30*4*1.0 |

| FKP01C10003 | 100*25*3*1.0 | FKP01S10003 | 430*30*4*1.0 |

| FKP01C10004 | 120*25*3*1.0 | FKP01S10004 | 630*30*4*1.0 |

| FKP01C10005 | 150*25*3*1.0 | FKP01S10005 | 300*35*4*1.0 |

| FKP01C10006 | 160*25*3*1.0 | FKP01S10006 | 400*35*3*1.0 |

| FKP01C10007 | 200*25*3*1.0 | FKP01S10007 | 500*35*3*1.0 |

| FKP01C10008 | 210*25*3*1.0 | FKP01S10008 | 600*35*3*1.0 |

| FKP01C10009 | 230*25*3*1.0 | FKP01S10009 | 400*35*4*1.0 |

| FKP01C10010 | 250*25*3*1.0 | FKP01S10010 | 500*35*4*1.0 |

| FKP01C10011 | 260*25*3*1.0 | FKP01S10011 | 600*35*4*1.0 |

| FKP01C10012 | 300*25*3*1.0 | FKP01S10012 | 610*35*4*1.0 |

| FKP01C10013 | 310*25*3*1.0 | FKP01S10013 | 630*35*4*1.0 |

| FKP01C10014 | 400*25*3*1.0 | FKP01S10014 | 640*35*4*1.0 |

| FKP01C10015 | 410*25*3*1.0 | FKP01S10015 | 300*40*4*1.0 |

| FKP01C10016 | 500*25*3*1.0 | FKP01S10016 | 400*40*4*1.0 |

| FKP01C10017 | 80*30*3*1.0 | FKP01S10017 | 500*40*4*1.0 |

| FKP01C10018 | 90*30*3*1.0 | FKP01S10018 | 600*40*4*1.0 |

| FKP01C10019 | 100*30*3*1.0 | FKP01S10019 | 640*40*4*1.0 |

| FKP01C10020 | 120*30*3*1.0 | FKP01S10020 | 610*38*6*1.0 |

| FKP01C10021 | 150*30*3*1.0 | FKP01S10021 | 1010*30*3*1.0 |

| FKP01C10022 | 160*30*3*1.0 | FKP01S10022 | 1010*30*4*1.0 |

| FKP01C10023 | 200*30*3*1.0 |

Welcome to inquire the customization sizeaccording to your need. |

|

| FKP01C10024 | 210*30*3*1.0 | ||

| FKP01C10025 | 250*30*3*1.0 | ||

| FKP01C10026 | 260*30*3*1.0 | ||

| FKP01C10027 | 300*30*3*1.0 | ||

| FKP01C10028 | 310*30*3*1.0 | ||

| FKP01C10029 | 330*30*3*1.0 | ||

| FKP01C10030 | 350*30*3*1.0 | ||

| FKP01C10031 | 400*30*3*1.0 | ||

| FKP01C10032 | 410*30*3*1.0 | ||

| FKP01C10033 | 430*30*3*1.0 | ||

| FKP01C10034 | 450*30*3*1.0 | ||

| FKP01C10035 | 500*30*3*1.0 | ||

| FKP01C10036 | 510*30*3*1.0 | ||

| FKP01C10037 | 600*30*3*1.0 | ||

| FKP01C10038 | 610*30*3*1.0 | ||

| FKP01C10039 | 630*30*3*1.0 | ||

| FKP01C10040 | 640*30*3*1.0 | ||

Production Flow

Strict producing processes ensure qualified products. One product goes through “order confirmation----computerized-----coding-----material----WEDM----welding-----relative grinding processes----balancing check-----QC. For QC processes, each finished cutter takes “appearance observation, thickness/angle/bore measurement, sampling and trial”, every cutter in customer’s hands can work perfectly.

Quality Control System: We always follow the high quality standard for production, from the material preparing to final product ready, all product will go through 3 inspections before we send them to you. Our professional teams will take care of your product and ensure the good and stable quality for all batches.

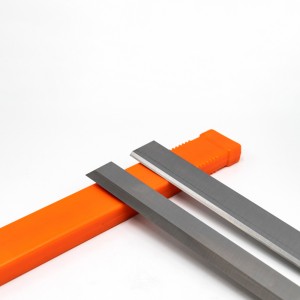

Packing

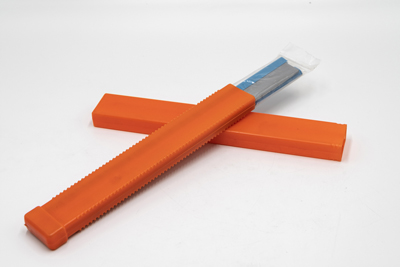

1.PVC to cover blade.

2. 3pcs In PVC box.

3. Packed by carton box with binding straps.

10pcs/box |

Delivery by UPS/DHL/FEDEX/EMS | |

| Shipping ways | Air transportation,Sea transportation,Land transportation,Express ,etc. | |

| Shipping Details | We can choose the fastest and economical shipping way for you. | |

Warranty

1. Fengke Tool planer knife are strictly inspeced after each process for cutter body thickness, size, flatness, bore, angle, welding, hardness, etc. We promise to ship 100% qualified product.

2. The blade is made of alloy which is high hardness but brittle. We have blade cover to well protect the knives, in case the damage caused during transportation (the damages include broken knife, unstable knife, cracked body), please take pictures when you receive it, we'd like to replace for you or reduce this amount in next order.

3. These are not in after sales service: the blade is not sharp when required grinding, broken blade by improper use, blade off, problems by self revising hole, unsuitable use purpose.